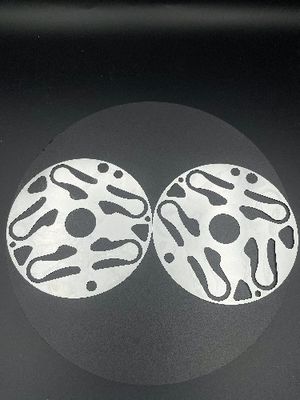

Product Overview

This Exhaust Valve Reed Shim is a precision-engineered replacement component designed specifically for Edwards E2S series two-stage, oil-sealed rotary vane vacuum pumps, including the E2S45, E2S65, and E2S85 models. As a critical internal part of the pump's exhaust mechanism, this reed shim is responsible for ensuring the efficient and sealed expulsion of gases, preventing backstreaming and maintaining the pump's specified ultimate vacuum pressure (e.g., 3.0E-03 mbar without gas ballast for the E2S85).

A worn or damaged exhaust valve reed is a common cause of performance loss in these reliable industrial pumps. This OEM-quality replacement part is manufactured to meet strict original equipment specifications, guaranteeing a perfect fit and reliable operation. It is an essential item for the routine maintenance and overhaul of these pumps, helping to restore and maintain their pumping speed and ultimate vacuum performance.

Key Features & Benefits

-

Precision Fit: Manufactured to exact Edwards OEM dimensions and tolerances for a perfect fit and seamless operation within E2S45, E2S65, and E2S85 vacuum pumps.

-

Restored Pump Performance: Replaces worn or damaged valve reeds to help the pump achieve its specified ultimate vacuum pressure and maintain consistent pumping speed, directly addressing issues like the inability to reach base pressure.

-

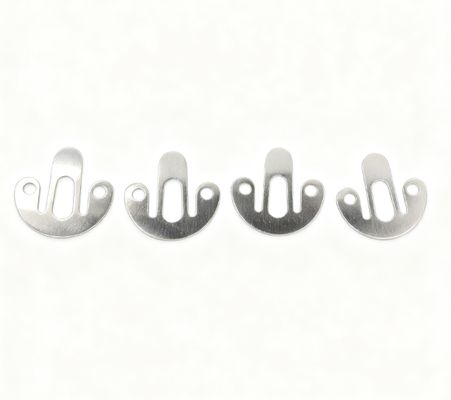

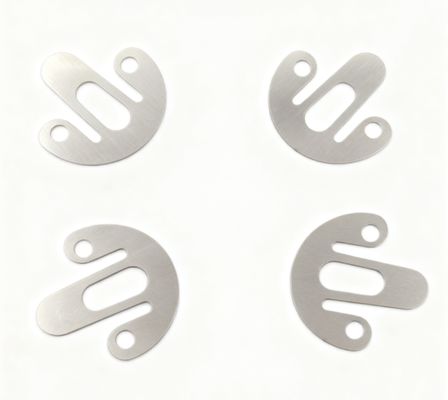

Durable Construction: Made from high-quality, fatigue-resistant spring steel or similar durable material, designed to withstand the continuous mechanical impact and chemical environment inside the pump's oil reservoir, ensuring a long service life.

-

Prevents Oil Backstreaming: A properly functioning exhaust valve is crucial for preventing oil and vapor from flowing back into the pump chamber and the vacuum system, protecting your process and product quality.

-

Easy Maintenance: This part is a key component in routine pump overhaul and maintenance kits, allowing for straightforward replacement by a qualified technician to resolve common performance issues.

Technical Specifications

Applications & Industries

This exhaust valve reed shim is essential for maintaining Edwards E2S series pumps, which are known for balancing performance, cost, and availability. These pumps are widely used in various sectors:

-

Industrial Processing: Plastic thermoforming, vacuum degassing, and impregnation.

-

General Manufacturing: Standard applications requiring reliable medium-vacuum.

-

Laboratory & Research: Environments where reduced noise levels (e.g., 60 dB(A) for E2S85 at 50Hz) are beneficial.

Compatibility Information

This exhaust valve reed shim is designed as a direct replacement for the following Edwards vacuum pump models:

-

Edwards E2S45

-

Edwards E2S65

-

Edwards E2S85

Verification is Crucial: Always verify your pump's full model number from the unit's nameplate before purchase. Cross-reference with your pump's parts list or consult the official documentation for confirmation.

Symptoms of a Failing Exhaust Valve Reed

Be aware of these common signs that may indicate the need for a valve reed replacement:

-

Poor Ultimate Vacuum: The pump cannot reach its base pressure (e.g., 3.0E-03 mbar) even after adequate pumping time.

-

Slow Pumping Speed: The time required to evacuate a vessel increases significantly.

-

Increased Noise: Unusual operational noises from the pump can indicate valve issues.

-

Oil Backstreaming: Visible oil mist or contamination in the vacuum line or chamber.

Why Choose Our Exhaust Valve Reed Shim?

-

Guaranteed Compatibility: Precision-manufactured to ensure perfect integration with your Edwards E2S series pump, restoring its original performance and reliability.

-

Proven Reliability: Made from quality materials to provide a durable and long-lasting repair, minimizing equipment downtime and supporting the pump's reputation for robust design.

-

Expert Support: We specialize in vacuum pump parts and can provide assistance to ensure you select the correct component.

Frequently Asked Questions (FAQ)

Q: How can I confirm this exhaust valve reed shim is compatible with my specific Edwards pump model?

A: This reed shim is designed for the E2S45, E2S65, and E2S85 models. For absolute certainty, please check the full model number on your pump's nameplate. Our support team can also assist with verification.

Q: Is this a genuine Edwards OEM part?

A: This is a high-quality aftermarket replacement part manufactured to strict OEM specifications, offering reliable performance and a perfect fit at a competitive price.

Q: What other components should I replace when performing maintenance?

A: For a comprehensive overhaul, we strongly recommend inspecting and replacing other wear parts simultaneously. Consider replacing the vanes (rotary blades), the entire maintenance kit which may include O-rings, seals, gaskets, and filters (air intake filter, oil filter). It is also an ideal time to change the vacuum pump oil.

Q: Do you provide technical data sheets for this part?

A: Specifications and compatibility information are provided here. For detailed engineering drawings, please contact our support team.

Shipping & Returns

-

We process and ship orders promptly to minimize your equipment downtime.

-

We stand behind our products with a clear and fair return policy for unused items.

-

This part is backed by a warranty against manufacturing defects.

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!